Trials Evaluate Technology, Showcase Retailer’s Commitment

We’ve all heard lots of hype about the value of variable rate (VR) technology but little validation has been available to back up claims. To help its customers decide if VR technology is right for their fields, Indiana-based Superior Ag Resources decided to team up with Winfield to test the technology in Greater Acre VR trials.

Results from these southern Indiana trials showed an average 6.8-bushel-per-acre yield advantage with the technology, and also highlighted Superior Ag’s commitment to innovation and service.

“It’s really about bringing confidence to our sellers as well as our growers that the technology we bring to the farm gate has value,” says Superior Ag Precision Ag Manager Todd Meyer. “It’s about Superior Ag doing our part in not only being innovative and progressive but also putting hard numbers to the value we bring.”

Implementing R7® Tool VR Prescriptions

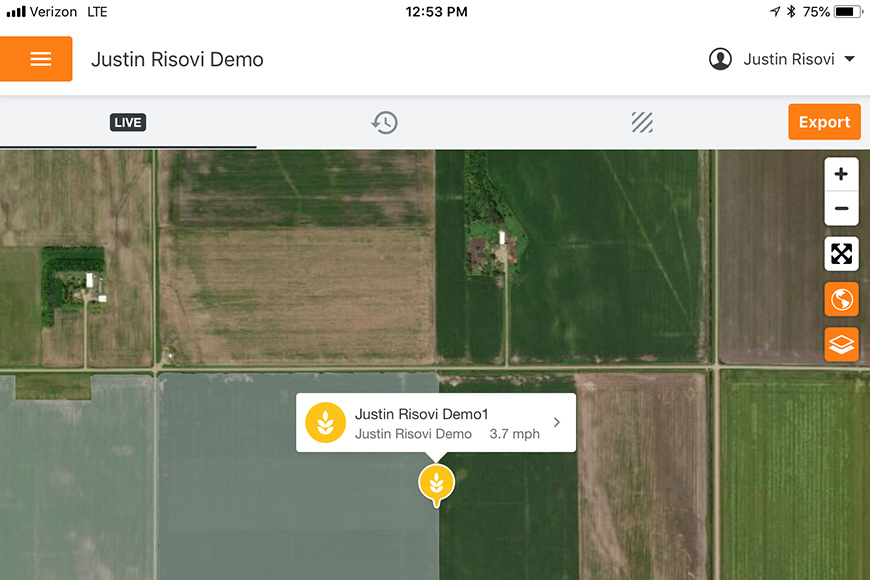

Conducted in conjunction with WinField, the Greater Acre Variable Rate trials began in 2013. Ten fields were part of the program initially. The trial protocol included VR seeding on corn with static check strips that were strategically inserted into a grower’s R7® Tool VR maps.

Using historical imagery through the R7® Tool as the foundation of each prescription, the growers, sellers and precision specialists worked hand-in-hand to develop customized field recommendations based on crop history, variability, hybrid placement and more. Validation continued throughout the summer with stand counts, tissue samples and imagery ground truthing.

Reaping Harvest Insights

At harvest, Superior Ag and Winfield specialists pulled data from 1- to 2-acre sections throughout each field to validate the results; samples from a static strip were compared with samples from a VR area. Both samples were within close geographical proximity to match yield environment and variability. Trial protocol required a minimum 6,000 population swing, with most populations ranging from 28,000 to 34,000. Multiple yield samples taken throughout each field were added and averaged.

With an 83 percent positive response rate, growers in these trials saw an average 6.8-bushel-per-acre return with the VR technology. Along with this valuable local trial data, Superior Ag and its growers gained other key learnings about what they can do to improve the quality of their data, including:

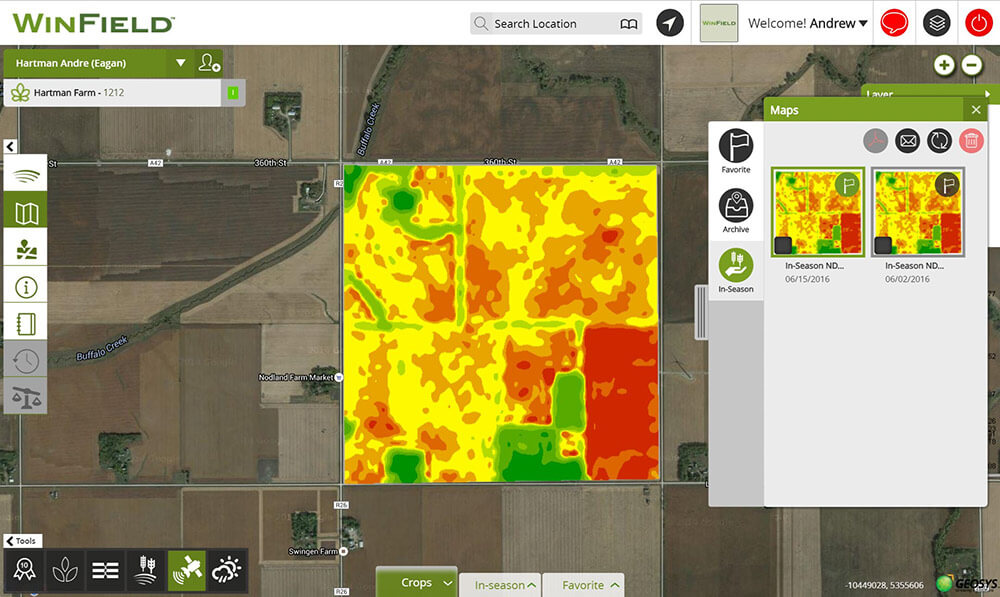

Using trial yield data and input costs, each field was analyzed in-depth through the R7® Tool profitability map to determine the net value of VR technology. The tool calculates profit distribution, showcasing where money was made or lost in each field, and how much.

Trial results and analysis have helped Superior Ag and its customers focus on accurate seed placement, rather than cutting seed costs. Farmers now know where increasing populations will have the potential for greater returns and, even more important, where dropping populations is the best option.

Starting their third year of Greater Acres trials, Superior Ag is expanding the program with nearly 1,000 trials taking place this year alone. The results will continue to help customers determine which ag technology is right for their operations.

Results from these southern Indiana trials showed an average 6.8-bushel-per-acre yield advantage with the technology, and also highlighted Superior Ag’s commitment to innovation and service.

“It’s really about bringing confidence to our sellers as well as our growers that the technology we bring to the farm gate has value,” says Superior Ag Precision Ag Manager Todd Meyer. “It’s about Superior Ag doing our part in not only being innovative and progressive but also putting hard numbers to the value we bring.”

Implementing R7® Tool VR Prescriptions

Conducted in conjunction with WinField, the Greater Acre Variable Rate trials began in 2013. Ten fields were part of the program initially. The trial protocol included VR seeding on corn with static check strips that were strategically inserted into a grower’s R7® Tool VR maps.

Using historical imagery through the R7® Tool as the foundation of each prescription, the growers, sellers and precision specialists worked hand-in-hand to develop customized field recommendations based on crop history, variability, hybrid placement and more. Validation continued throughout the summer with stand counts, tissue samples and imagery ground truthing.

Reaping Harvest Insights

At harvest, Superior Ag and Winfield specialists pulled data from 1- to 2-acre sections throughout each field to validate the results; samples from a static strip were compared with samples from a VR area. Both samples were within close geographical proximity to match yield environment and variability. Trial protocol required a minimum 6,000 population swing, with most populations ranging from 28,000 to 34,000. Multiple yield samples taken throughout each field were added and averaged.

With an 83 percent positive response rate, growers in these trials saw an average 6.8-bushel-per-acre return with the VR technology. Along with this valuable local trial data, Superior Ag and its growers gained other key learnings about what they can do to improve the quality of their data, including:

- Planter calibration. Because achieving quality data begins with planting, proper planter calibration is a fast, easy way to eliminate skewed results.

- Hybrid placement. The decisions that go into accurate population prescriptions depend on the characteristics of the hybrid being planted. A hybrid with a high response to population (RTP) will be able to handle a much higher bump in population than a hybrid with a low RTP score.

Using trial yield data and input costs, each field was analyzed in-depth through the R7® Tool profitability map to determine the net value of VR technology. The tool calculates profit distribution, showcasing where money was made or lost in each field, and how much.

Trial results and analysis have helped Superior Ag and its customers focus on accurate seed placement, rather than cutting seed costs. Farmers now know where increasing populations will have the potential for greater returns and, even more important, where dropping populations is the best option.

Starting their third year of Greater Acres trials, Superior Ag is expanding the program with nearly 1,000 trials taking place this year alone. The results will continue to help customers determine which ag technology is right for their operations.